- Home

- Products

- Polymer Fiber Spinning Spinneret

- Polymer Fiber Spinning, Braid Tube Reinforced Spinning Spinneret

Polymer Fiber Spinning, Braid Tube Reinforced Spinning Spinneret

Introduction

For NIPS membranes and TIPS membranes prepared from homogeneous materials, the membrane strength is entirely provided by the separation membrane material itself. In order to enhance the mechanical strength of the hollow fiber membrane, one or two layers of a casting liquid can be coated onto the outer layer of the braided tube, with the polymer film formed and bonded to the braided tube through a solution phase transformation process. We offer braided tube coated follow fiber film spinnerets that meet all of your requirements for coating one or two layers of the casting liquid on the outer layer of the tube.

Suitable materials

PVDF (Polyvinylidene Fluoride), CA (Cellulose Acetate), PVC (Polyvinyl Chloride), PES (Polyethersulfone), PSF/PSU (Polysulfone), PA (Nylon, Polyamide), PAN (Polyacrylonitrile)

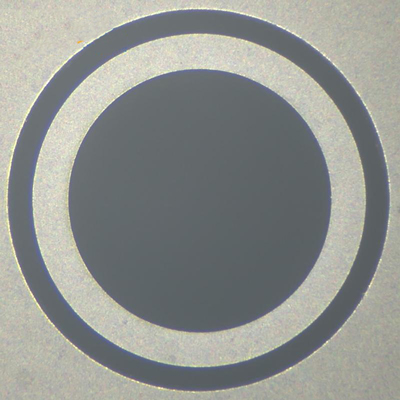

Conventional design

Conventional design Independent design

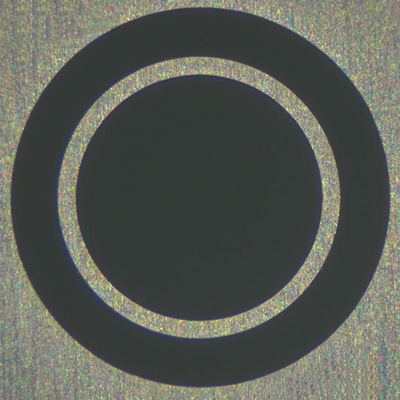

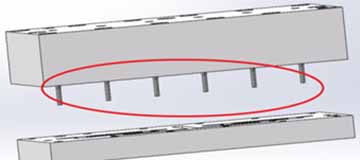

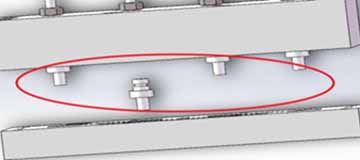

Independent design

We can provide a removable spinneret design that differs from traditional spinnerets. In a traditional spinneret, each hole cannot be independently replaced or disassembled. If a problem arises in one, the spinneret in its entirety needs to be repaired or scrapped. Our spinnerets are designed so that each hole can be individually replaced, without the hassle of fixing the entire machine.

Parameter| No. | General Specification | Application | Design Type | Type |

| 1 | 1.8/1.5/1.2 | Braided Tube | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 2 | 2.4/2.1/1.8 | Braided Tube | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 3 | 2.6/2.2/1.9 | Braided Tube | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 4 | 2.6/2.3/2.0 | Braided Tube | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 5 | 2.7/2.2/1.9 | Braided Tube | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 6 | 3.0/2.2/1.95 | Braided Tube | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

| 7 | 3.1/2.8/2.5 | Braided Tube | Conventional design/ Independent design | Single-aperture/ Multi-aperture |

Trustech is a leading polymer fiber spinning spinneret manufacturer, by combined with advanced technology of fiber spinning process and equipment from Germany we can fabricate high quality spinneret, we can offer spinnerets used wet spinning, dry spinning, melt spinning for different fiber spinning process users, we have had clients who used our spinnerets to produce hollow fiber membrane for different filtration applications.

Index

hollow fiber membrane, wet spinning, melt spinning, drying spinning, spinning process

Shanghai Trustech Technology Development Co., Ltd.

Add.: Building 12, No.851 Xinghua road, Jiading district, Shanghai 201812

Tel.: +86-21-69899973